In the vibrant landscape of food processing technology, the retort food machine attracts attention as an essential component in making sure food durability, high quality, and safety and security. As customers end up being more health-conscious and demand greater standards of food security, the function of machinery like the retort autoclave has increased considerably. These innovative machines utilize a method called retort sterilization, which entails home heating food in a sealed container under high pressure to eliminate dangerous microorganisms, thus extending service life and keeping nutritional stability. The procedure not just decontaminates the food yet additionally protects its flavor and structure, making it a favored choice for food manufacturers worldwide.

Retort machines come in different versions and sizes, fitting various scales of production, from small procedures to large industrial demands. The adaptability of retort machines allows food processors to package a vast array of products, consisting of vegetables, meats, and ready-to-eat dishes, efficiently satisfying the diverse choices of consumers. With the advancement of food production equipment, contemporary retort machines are engineered for uniformity, performance, and power financial savings, making them invaluable in today's open market. The price of retort machines can vary considerably based on specifications, abilities, and the manufacturer, which enables potential buyers to choose versions that best fit their functional demands and spending plan.

The global food processing equipment manufacturers continually introduce to enhance the efficiency of retort machines. These improvements not only purpose to enhance the sterilization procedure however additionally to minimize water and energy usage, thereby lessening environmental influence. For companies aiming to purchase a retort machine, it's essential to take into consideration elements such as throughput ability, temperature control, and the details needs of the foodstuff entailed. Understanding these variables can cause better decision-making and eventually higher item top quality.

Safety and security criteria in the food market are vital, and making use of a retort sterilizer helps fulfill extensive health and wellness regulations by making certain that all pathogens are properly removed. The usage of pressure autoclaves, which are similar to retort machines but often employed in a more comprehensive variety of applications outside food processing, underscores the versatility of autoclave technology as a whole.

An emerging trend among food mill is the need for automation within the retort and product packaging procedures. Industries are progressively transforming to completely automated systems that incorporate perfectly with retort machines, boosting production efficiency and reducing labor prices. This change not just contributes to more consistent item top quality but additionally enables manufacturers to react promptly to market adjustments. As consumer preferences shift towards comfort and ready-to-eat dishes, the importance of reliable food processing equipment can not be overemphasized, and retort machines play an essential role in fulfilling this demand.

From little artisanal operations to comprehensive business kitchen areas, the retort machine has actually ended up being synonymous with food security and preservation. The retort procedure guarantees that even as food production ranges, security and honesty are not jeopardized.

Looking into well-known players in the food processing equipment industry enables purchasers to contrast features, reliability, and support services. Retort machines represent a long-term investment for food manufacturers; for this reason, picking a top quality machine is extremely important in achieving sustained functional success.

Additionally, ecological sustainability is ending up being a vital element of food production, with many manufacturers looking for greener processing techniques. Retort technology has actually additionally adapted to these needs, with improvements concentrated on energy efficiency and lasting materials. Ingenious layouts decrease the carbon impact related to food processing while maintaining high criteria of food safety. As consumers check here significantly favor sustainably generated products, businesses outfitted with these green retort machines will certainly locate a considerable advantage in the industry.

Food security and law firms around the world promote for using trusted processing equipment to battle foodborne ailments, providing a more inspiration for business to take on retort sterilization innovation. Modern retort machines commonly incorporate sophisticated tracking systems that track and document processing conditions in real-time, improving traceability and liability within the food supply chain.

The technological developments within retort sterilizers and autoclaves have actually made it possible to streamline the production process significantly. This automation and accuracy drastically reduce the threat of human error while maximizing procedure effectiveness. Advanced sensors and software application enable drivers to keep an eye on several processes simultaneously and make quick changes click here as needed, improving functional versatility. This ability to adapt swiftly to various products and differing production demands settings businesses to meet the ever-changing expectations of customers.

Furthermore, integrating retort machines into food processing equipment financial investments shows a commitment to high quality that can establish a company apart from its competitors. Customers today are acutely aware and well-informed of the food processing approaches behind their purchases. For that reason, utilizing modern technology that guarantees safety and security and high quality can be a solid selling point. The capacity to offer transparency relating to processing approaches, consisting of the usage of retort sterilization, can develop client commitment and boost brand name online reputation.

In summary, the duty of retort food machines and autoclaves in modern food processing can not be overstated. These machines are essential in providing risk-free, premium food products that fulfill the high requirements consumers expect. As technology proceeds to evolve, the area of food processing is set to successfully tackle brand-new challenges while adjusting to shifting customer needs. From performance and safety and security to sustainability and automation, retort machines and their sustaining modern technology create the foundation of a reputable and forward-thinking food production system. Whether it is large industrial autoclaves or specialized food retort machines, the continued investment in this modern food processing equipment manufacturers technology will definitely drive the landscape of food safety and security and top quality requirements right into the future.

Daniel Stern Then & Now!

Daniel Stern Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Jason J. Richter Then & Now!

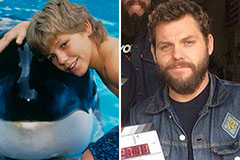

Jason J. Richter Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!